Product Information

Creating a Sustainable Future with World-Class Control Technology

Optimizing production lines with world-class control technology. We provide comprehensive support from design to installation and commissioning of control panels for diverse industries including automotive, semiconductor, and food processing. As one of the few UL508A certified manufacturers in Japan, we supply equipment that complies with international standards.

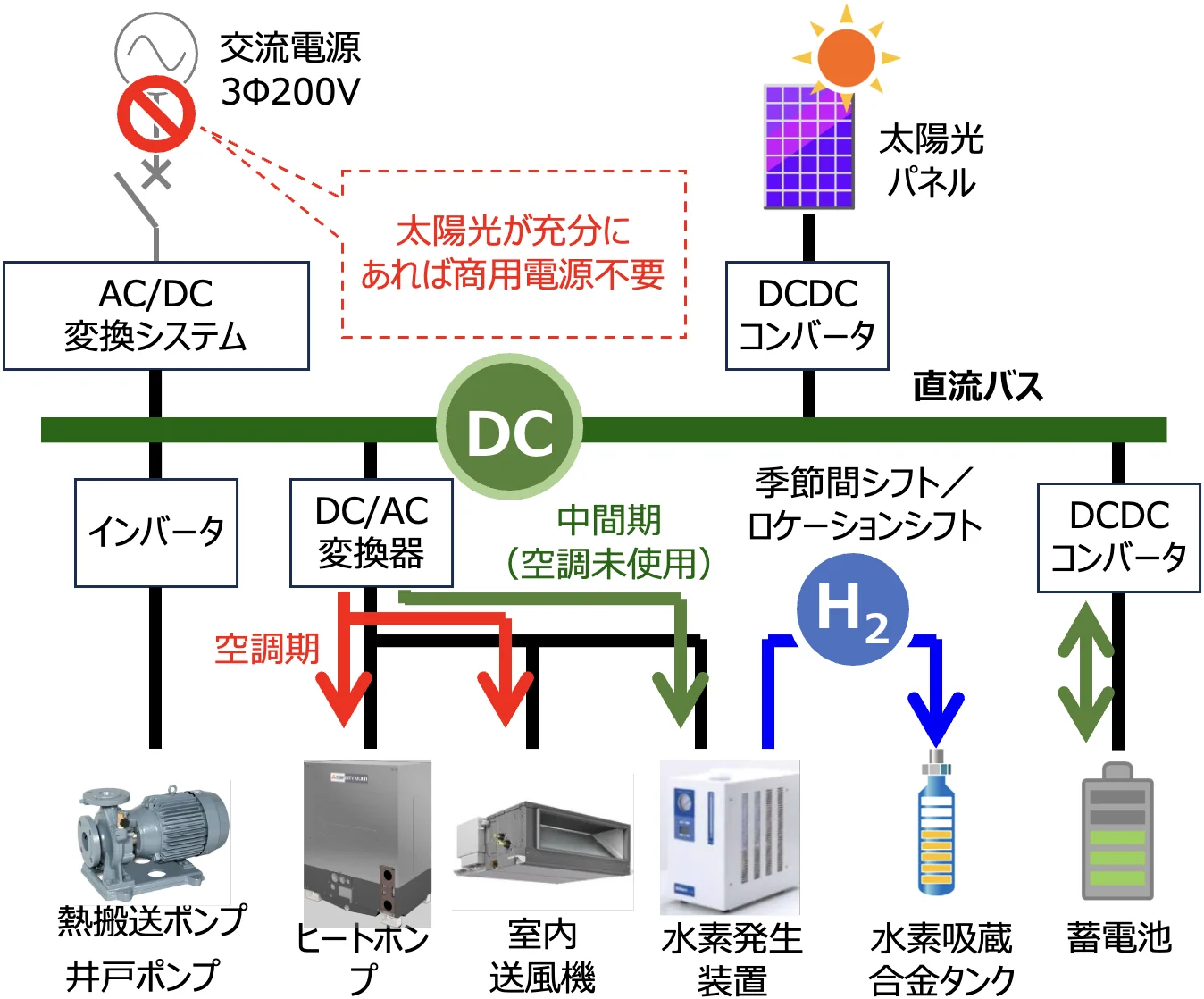

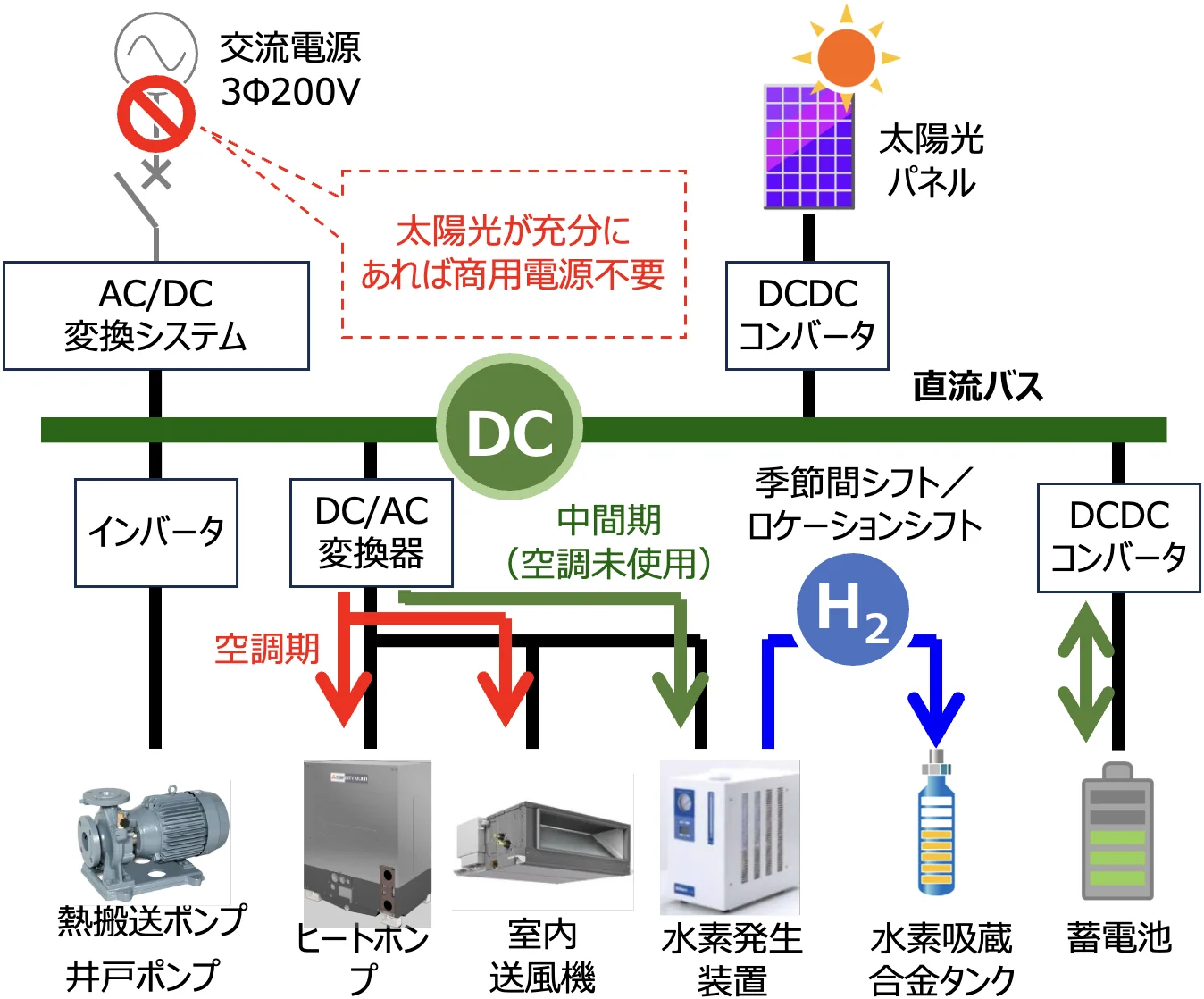

Converting existing equipment to renewable energy operation without modification. Our unique model integrates renewable energy sources like solar and wind power with energy storage systems, enabling existing inverters and servos to operate on renewable energy. This significantly reduces CO$2082 emissions and contributes to lowering product carbon footprints.

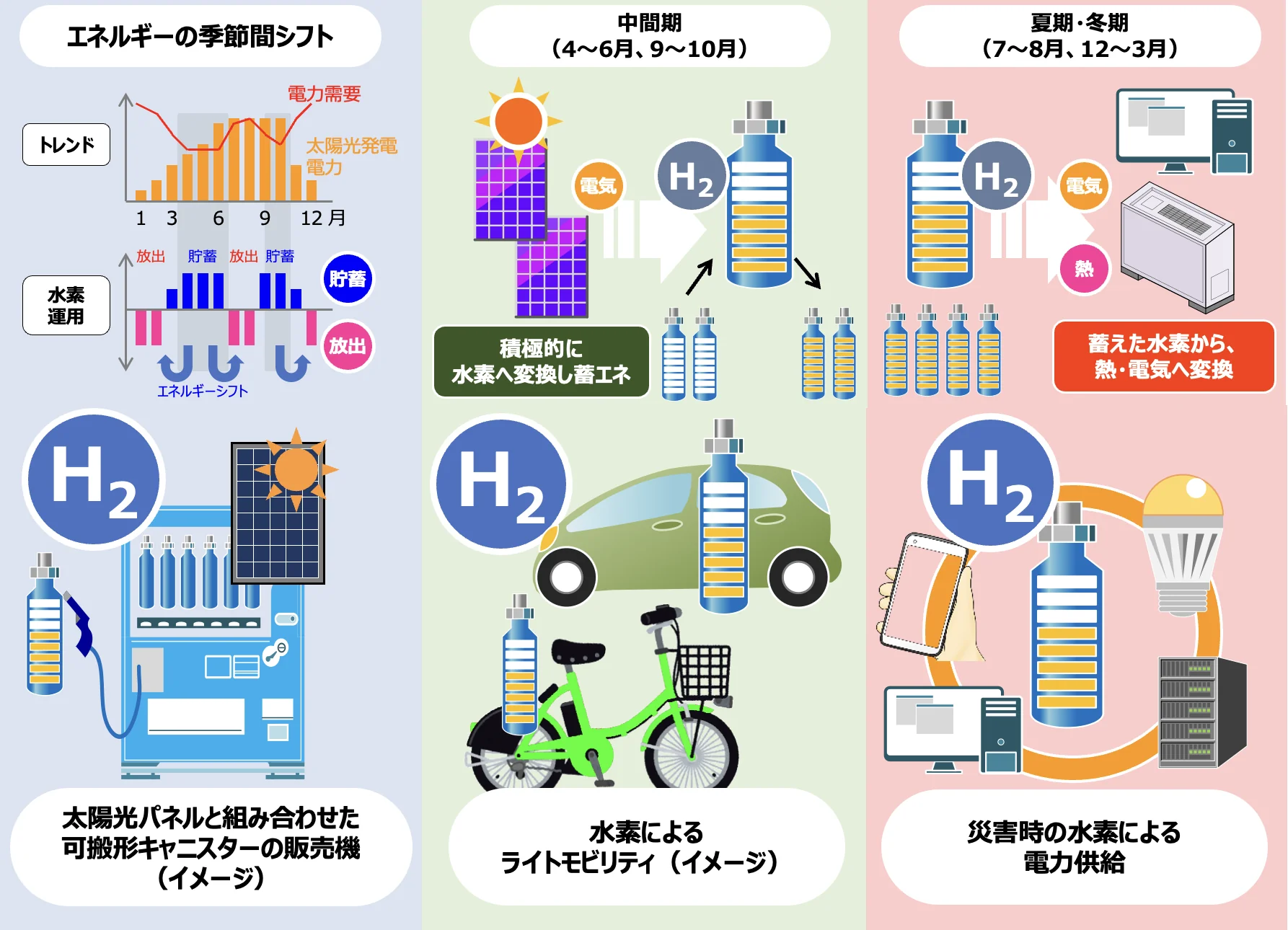

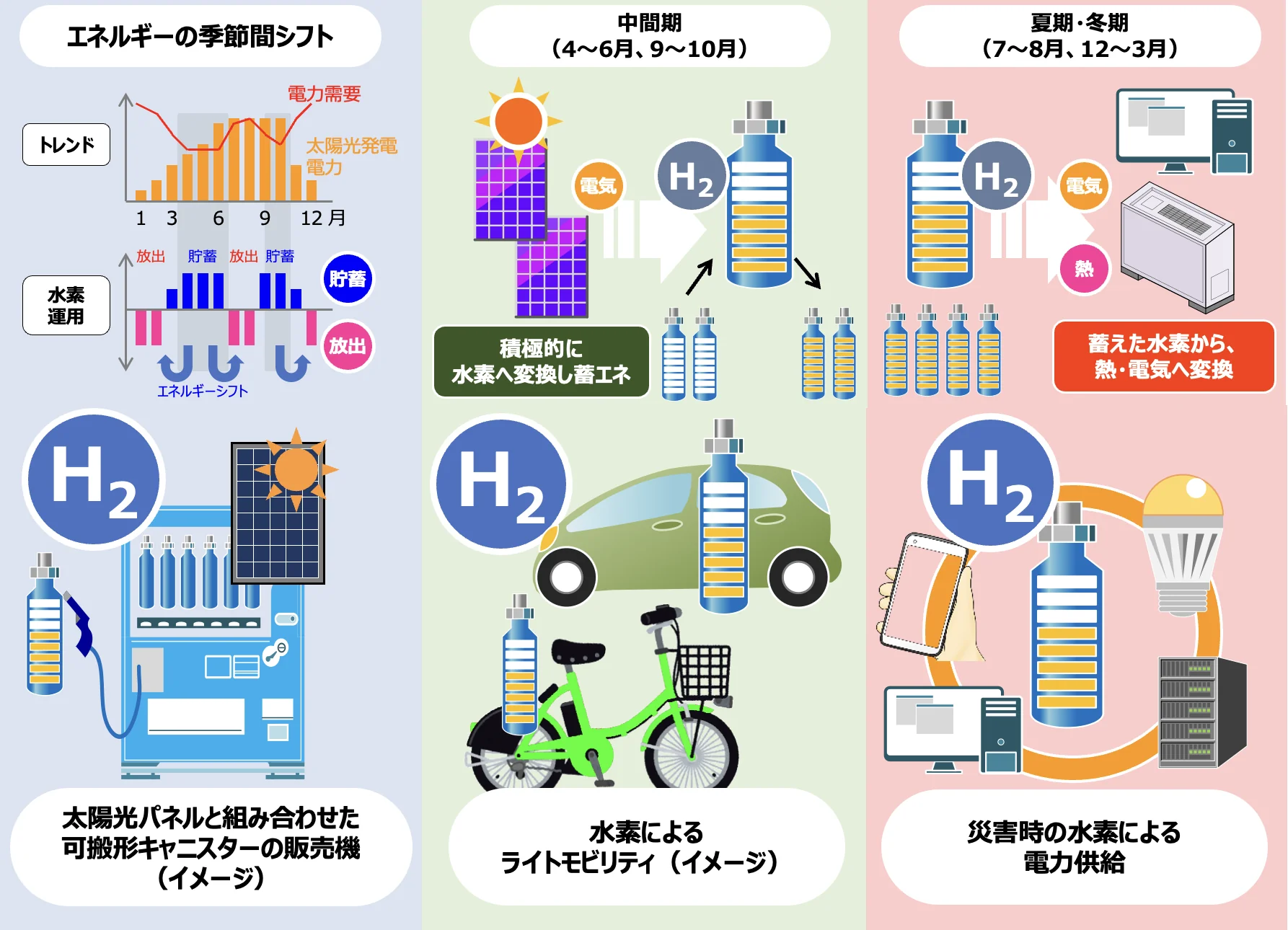

Bringing next-generation energy "hydrogen" to everyday industries. By combining hydrogen storage alloys with fuel cells, we achieve seasonal shifting of renewable energy. Stored hydrogen can be utilized for light mobility and equipment power sources. We are advancing verification through industry-academia-government collaboration.

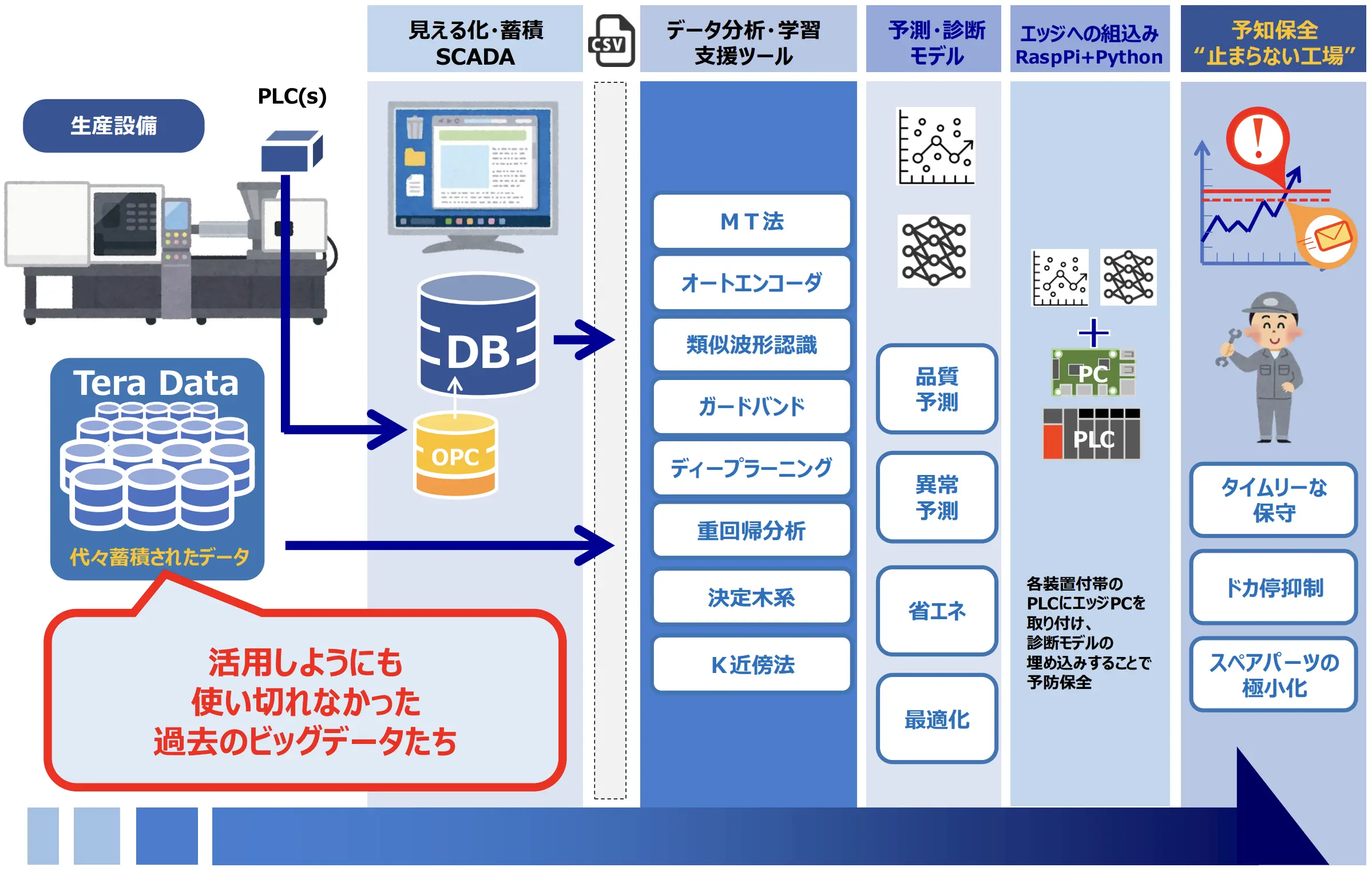

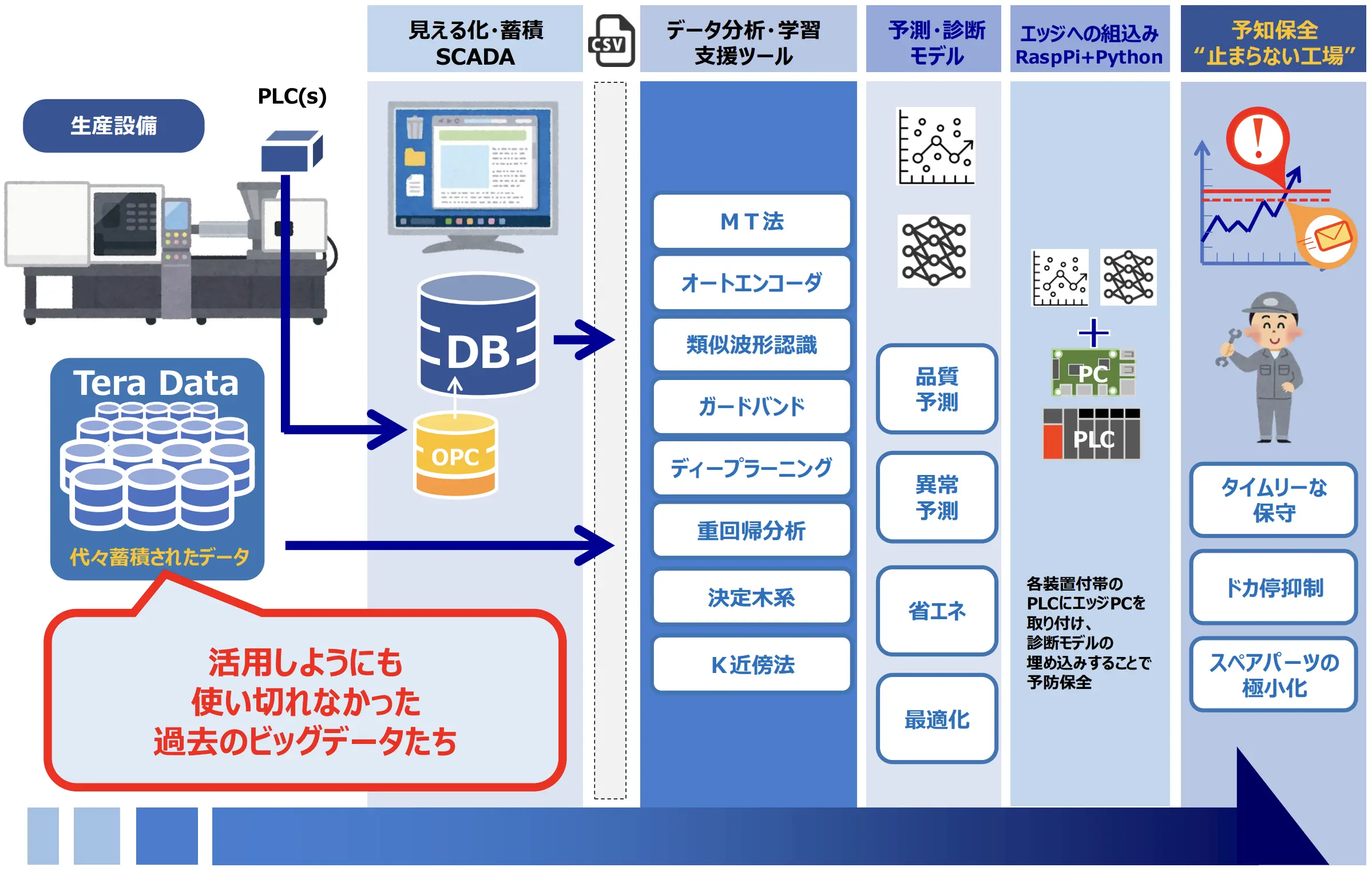

Protecting production lines with data. By analyzing operational data from IoT sensors with AI, we detect signs of equipment failure. Our predictive maintenance system goes beyond traditional "visualization" to achieve zero major shutdowns (long-term stops).

Our Services

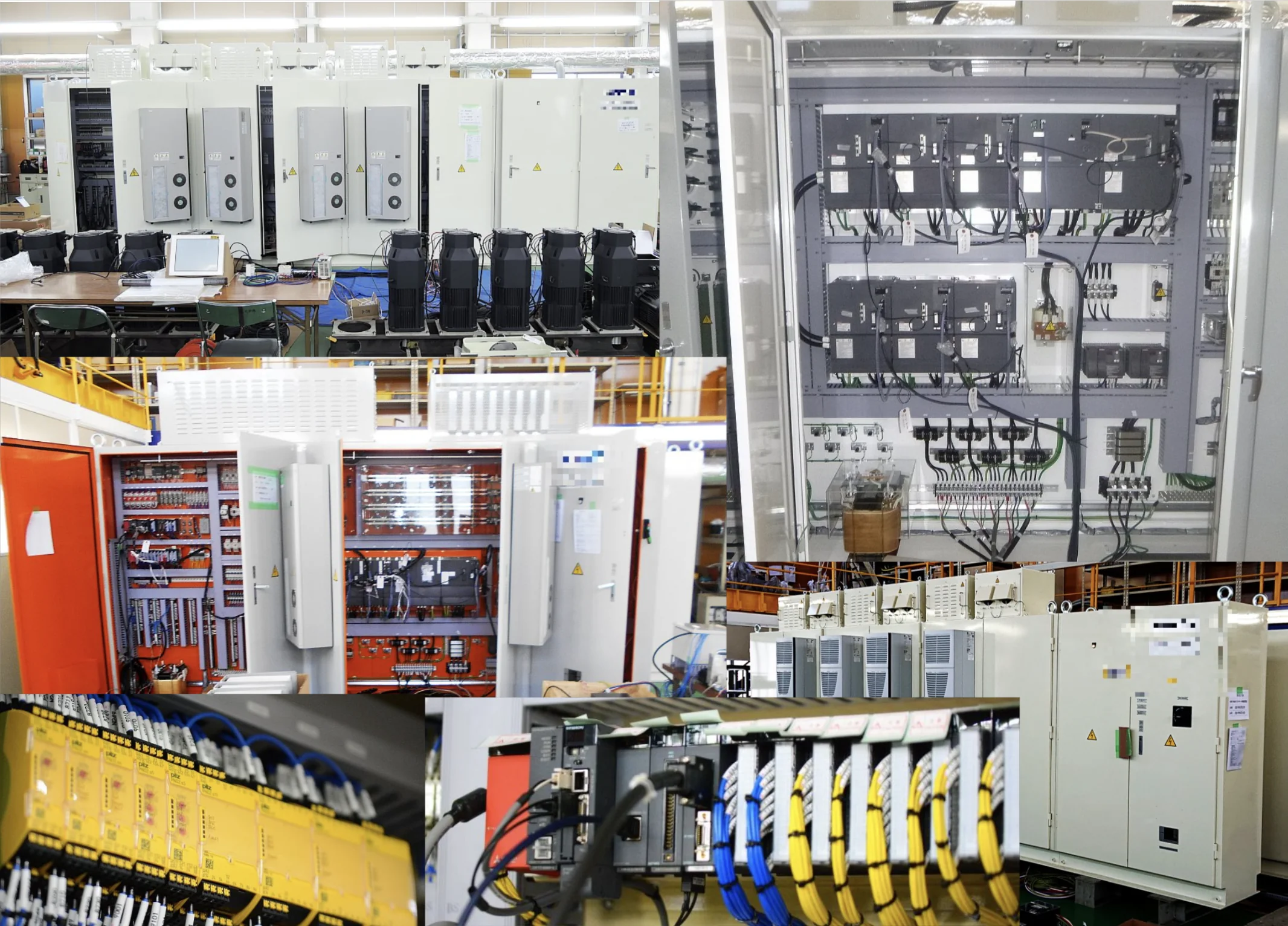

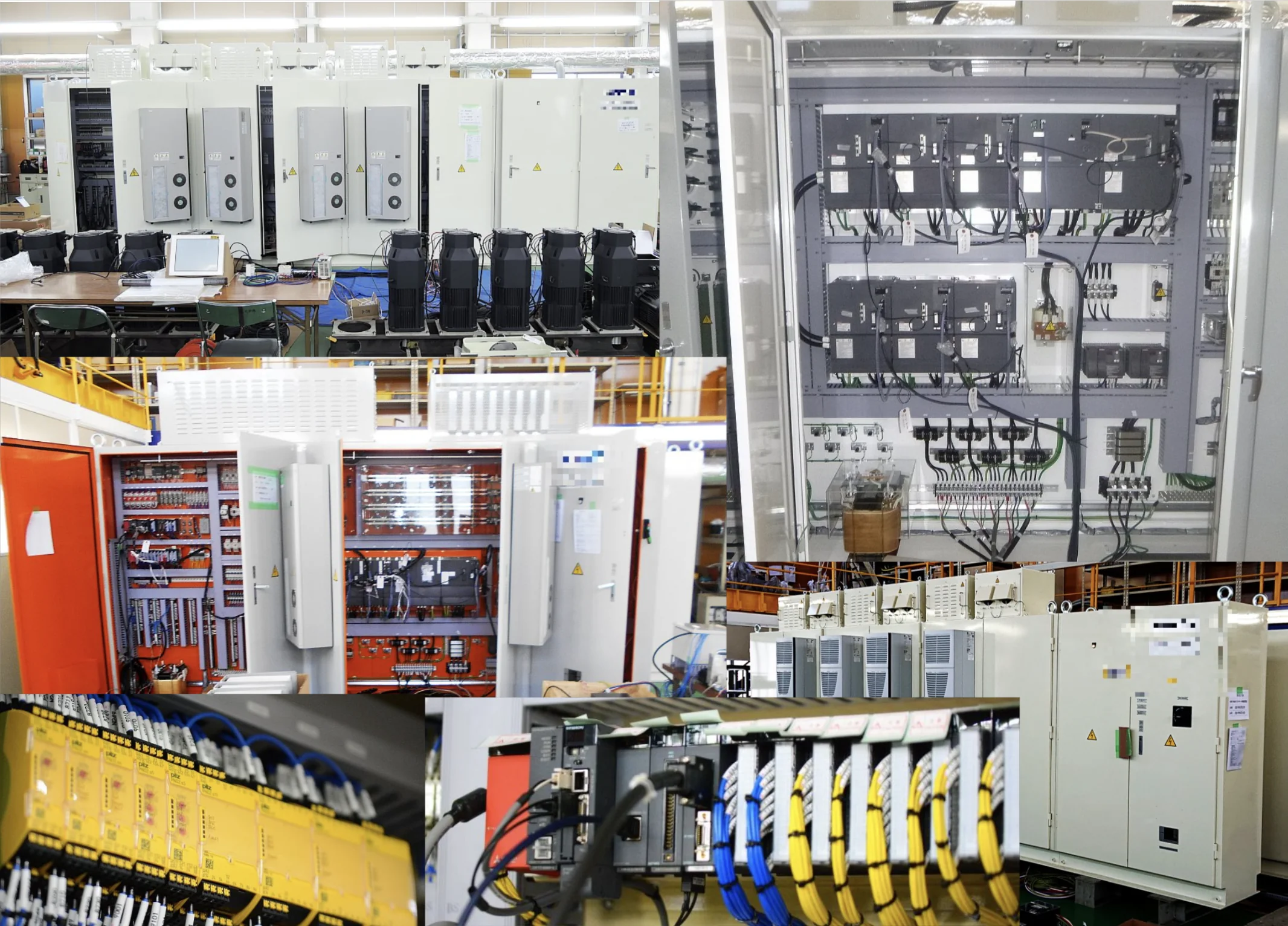

01 PLC Control Systems

Creating the brain of industrial machinery with advanced control technology. We provide comprehensive support from design to manufacturing and commissioning of automatic control systems centered on PLCs. By combining various sensors, actuators, and motion control, we achieve high-speed, high-precision, and high-reliability line control. Compliant with domestic and international control standards (UL/CE), we support automation across all industries.

We use the DC control technology we have built through our work so far.

We connect “generate,” “store,” and “use” with DC power

and build energy systems that can run on their own.

We now join many national and prefectural projects,

and we even design equipment in-house that is featured in the global science journal Nature.

It is not only “big companies” that can change society.

Small companies from Ishikawa like ours can also surprise the world.

Would you like to help us build the energy model of the future?